Our useful FAQ is designed to be as clear as possible. If the information below does not answer your query, please contact us. Our team will endeavour to reply to all questions within 24 hours.

Most common questions

-

No. GasStop will not shut-off in the event of a minor/slow/progressive leak. Refer to “How does GasStop define a sudden and catastrophic leak?” for a detailed breakdown of the limitations of the shut-off function here: https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1770_28

To achieve a balance between protection and operating convenience, GasStop cannot be calibrated to shut-off the propane system for all types of leaks. However, GasStop can be used to test for all types of leaks, here is how:

It is highly recommended that you always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to conveniently test your entire system from the propane cylinder locker. This test is known as a ‘visual lock-up pressure test’, also known as a pressure tightness test or a pressure decay test. We also encourage the use of soapy water to visually identify leaks by manually inspecting the lines and joints for bubbles (showing the escape of propane).

This test can only be carried out prior to normal gas usage.

To test your system for leaks:

- Set up your system (with your GasStop) as described in the user manual. Turn off the service valve on the gas cylinder. Now turn off all of your gas appliances. There should be no flow of propane in your system at this stage of test procedure.

- Now turn the propane cylinder back on at the service valve (make sure it is fully on). Keep all appliances off for the time being.

- Pump the pressure gauge on the GasStop up and down steadily and fully at least 4 to 6 times.

- The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder service valve is not open, GasStop has shut-off (or can’t pressurize), the propane has run out or you have not carried out sufficient pumping. Contact us directly to troubleshoot this step if necessary.

- Now turn off the service valve on the propane cylinder. Register the exact position of the needle on the gauge. Wait for 10 minutes.

- At this point, pressurised propane is now held between the GasStop and your appliances.

- If the needle has dropped from its initial registered position within 10 minutes there may be a leak (pressure decay). Do not use the gas system until the leak has been identified and/or repaired by an approved propane service technician and/or specialist.

- If, after pumping, the needle remains in the same position for at least 10 minutes, you can carefully start to use the system.

-

It is important to note that using propane whilst driving is regulated by country and by state. Please consult with your RV manufacturer, a certified professional and the appropriate regulation before using gas while driving. GasStop can be used on your gas system while driving, but it is not recommended to use propane while driving. If installed correctly, a GasStop will offer protection against a sudden and catastrophic leak (for a detailed breakdown of the limitations of the shut-off function refer to: https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1770_28 )

Furthermore, GasStop can be installed alongside a crash sensor valve. A crash sensor valve may offer added protection in the event of a collision. GasStop is not a crash sensor valve. For limitations on a crash sensor valve please refer separately to the manufacturer/user manual of your specific device.

The two safety devices together fulfil separate yet important functions in the overall safety of your propane system.

-

Yes. GasStop must be used with a propane pressure regulator to function correctly. GasStop is designed to be used with regulators rated up to 20″ W.C.

-

In the USA, propane cylinders have inbuilt OPD valves. An OPD valve is an overfill protection device, and as the names suggests will prevent the overfilling of a propane cylinder. GasStop is an Excess Flow Valve (EFV). It is designed to shut down 100% of the flow of propane in the event of a sudden and catastrophic leak. To protect against sudden and catastrophic leaks make sure you install a GasStop.

-

No, it reads the pressure of the propane under load/usage. Refer to: “Is the pressure gauge useful?” for a more detailed breakdown of what the gauge can be used for and what it can tell you.

-

If you need a better viewing angle of the gauge, rotate the GasStop (before tightening the nut) no more than 45 degrees from the vertical. For optimum performance (especially during colder temperatures) orientate your GasStop so that the gauge is facing the sky.

-

Yes, GasStop is UL listed. Furthermore each and every GasStop is rigorously tested. All of our testing is evidenced via a global third-party test auditor.

-

The propane pressure gauge is a very useful, multipurpose tool.

The propane pressure gauge is a very useful, multipurpose tool.- The gauge indicates when the propane cylinder is almost empty (a decline in the vapour pressure curve). The gauge does not indicate the exact amount of liquid propane left in the propane cylinder.

- A steady pressure reading (the needle is stable in the green or low part of the yellow zone) only indicates that there is propane in the cylinder.

- If the needle is pointing to:

– HIGH: Increased gas pressure.

– GAS: Normal gas pressure.

– LOW: Low gas pressure. Liquid propane may have been used up and your appliances are now drawing from the remaining propane gas vapour, represented by a pressure drop. We estimate that when the needle is in the red zone you have approximately 30 minutes left of propane use. - As GasStop is directly installed into the cylinder there are a few variables that can affect unregulated pressure, namely: temperature, amount of liquified gas vs rate of vaporization, gas type and gas purity. There may also be other irregularities which affect the pressure reading.

- As per the instructions, it is advised to run your propane for a small period of time to have a better indication of gas pressure. This allows the propane/pressure to reach something called “phase equilibrium”. Further to this point there is a “vapour pressure curve”, this is why it is recommended to run the bottle for a short while to allow for this process.

NB the gauge is also useful to represent the following:

- Visual evidence of pressure decay (a leak) in a lock-up pressure test scenario.

- Visual evidence of high pressure

- Visual evidence of a shut-off

- Visual evidence of an activated and stable system

- Visual evidence of variable/unstable pressure

-

Flow limiters built-in to common US propane connectors may not shut the propane off completely in the event of a sudden and catastrophic leak, they often just limit the flow. GasStop completely shuts off the 100% of the supply of propane in the event of a sudden and catastrophic leak. GasStop will give the operator a visual representation of the status of the propane flow and pressure.

-

Sudden and/or aggressive movement can disturb the equilibrium of the GasStop shut-off mechanism causing the unit to shut-off unexpectedly. Please be vigilant when travelling on uneven or bumpy roads.

-

In humid, cool or changeable weather conditions, condensation may appear on the inside surface of the transparent gauge face. This happens as the air trapped inside the gauge condenses, forming small surface water droplets on the plastic casing. Although this is not common, it will not affect the operation of the GasStop. To rectify the problem, remove your GasStop from the gas system and leave the product in a warm and dry location. After a while the condensed water will evaporate and the visual appearance of the gauge will return to normal.

-

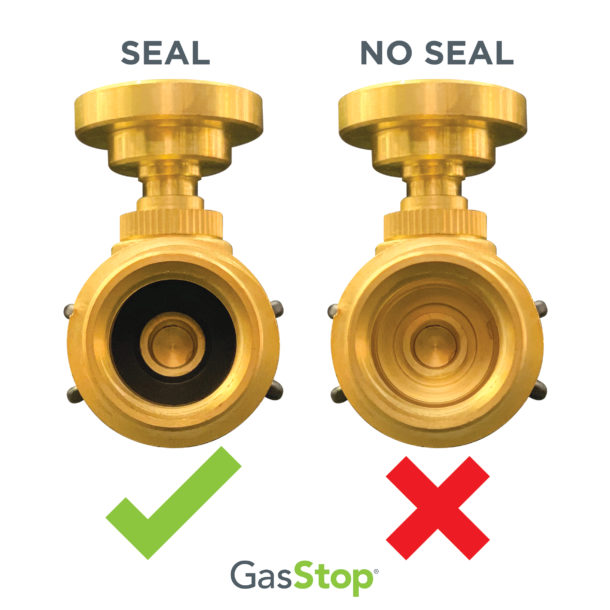

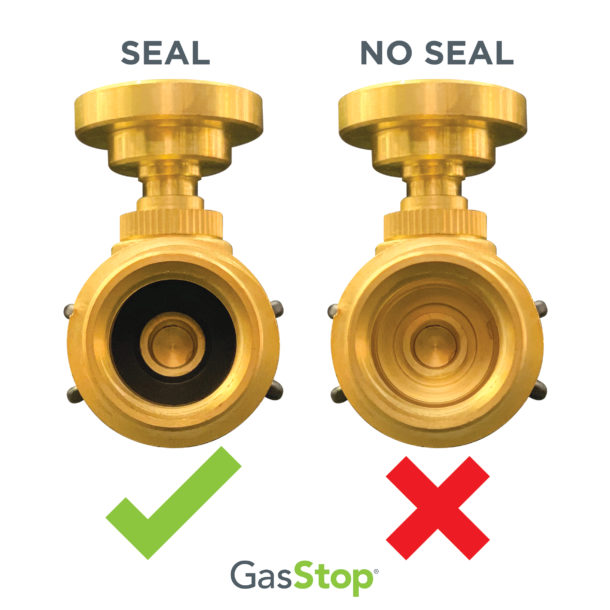

It is very important to check your GasStop (and any propane accessory or hose you use) for missing or damaged rubber seals before use. If you smell or hear propane during use, shut down the propane supply immediately and check your system for damaged and/or missing seals. As a point of reference we have included an image below demonstrating a GasStop with and without a seal. If your GasStop has a missing seal, please do not use it and contact our customer service team for a replacement.

-

You may notice that in colder temperatures (approaching 0°C/32°F), an EFV (GasStop) may shut-off more readily when used with higher demand appliances and/or on longer length pipework. For optimum performance during colder temperatures orientate your GasStop so that the gauge is facing the sky and make sure you push down on the gauge fully at least 5-6 times. .

-

No. GasStop has a maximum range of protection. GasStop provides protection for up to 19 ft of 5/16″ (8 mm) ID propane line at 11″ W.C. and approximately 16 °C, under light appliance use such as a refrigerator.

On systems with a ½″ trunk line, the same EFV typically provides protection for up to ~21 ft under equivalent conditions.

Actual protection distance may be reduced by regulator pressure droop, additional fittings, or higher simultaneous gas demand

Using the GasStop safely

-

As an example, if you have a GasStop, an extendastay and a regulator installed on your Class A vehicle this may be considered to be a long installation. It is advisable that you take steps to reduce the chances of these accessories moving horizontally and vertically (e.g. during driving) while attached to the propane cylinder, this can be done by a gas specialist. Doing so will reduce the forces and strain on the connectors. If you use a 5th wheel or travel trailer, and have concerns about the length of your system, consider using a GasGear 90 degree high pressure hose, visit www.gas-gear.com for more information.

-

For optimum results we recommend orientating the GasStop gauge towards the sky. GasStop has been designed and tested in this orientation. If space is an issue, the gauge can be orientated no lower than 45 degrees from the sky. If you start to experience unexpected shut-offs, reorientate the gauge back towards the sky. Please note, it is very important not to twist the GasStop during the orientation phase of installation. Orientate the GasStop first, then tighten it to the propane cylinder afterwards.

-

If you need a better viewing angle of the gauge, rotate the GasStop (before tightening the nut) no more than 45 degrees from the vertical. For optimum performance (especially during colder temperatures) orientate your GasStop so that the gauge is facing the sky.

-

For tight fit installations many customers will use a GasGear 90 degree high pressure pigtail hose, more information can be found here: www.gas-gear.com . A 90 degree pigtail will dramatically reduce the length of the system. Alternatively, some customers have solved this issue by rotating their propane cylinders to either the inside or the outside corner to accommodate for the additional length created by the GasStop. This orientation may sometimes require a longer pigtail to reach the regulator. We encourage you to contact a gas specialist if you have any doubts, alternatively please also contact our team directly.

-

For tight fit installations many customers will use a GasGear 90 degree high pressure pigtail hose, more information can be found here: www.gas-gear.com . A 90 degree pigtail will dramatically reduce the length of the system. Alternatively, some customers have solved this issue by rotating their propane cylinders to either the inside or the outside corner to accommodate for the additional length created by the GasStop. This orientation may sometimes require a longer pigtail to reach the regulator. We encourage you to contact a gas specialist if you have any doubts, alternatively please also contact our team directly.

-

All GasStop models are calibrated for propane gas use only – this is clearly stated on the instructions and is marked on the GasStop gauge face.

Autogas LPG very often has a variable and/or high butane composition and may affect the shut-off performance of the GasStop. Autogas is therefore not suitable for use with GasStop.

-

GasStop is not rated for marine use (namely in salt water conditions where ammonia exposure may be present). Please contact a marine gas specialist for further information on marine gas installations.

-

Sudden and/or aggressive movement can disturb the equilibrium of the GasStop shut-off mechanism causing the unit to shut-off unexpectedly. Please be vigilant when travelling on uneven or bumpy roads.

-

It is very important to check your GasStop (and any propane accessory or hose you use) for missing or damaged rubber seals before use. If you smell or hear propane during use, shut down the propane supply immediately and check your system for damaged and/or missing seals. As a point of reference we have included an image below demonstrating a GasStop with and without a seal. If your GasStop has a missing seal, please do not use it and contact our customer service team for a replacement.

-

GasStop cannot be used on a 1lb tank, it can only be used on either 20lb or 30lb tanks. Here’s why:

A propane cylinder’s flow rate is driven by:

1. Vapor pressure inside the tank (set by temperature)

2. Flow restrictions (valve, fittings, hose)

3. Vaporization rate (how fast liquid propane boils into gas)

The maximum flow rate on a 1 lb tank is about 6 SCFH, given the above mentioned flow restrictions and the rate of vaporization. This is not enough to trigger an EFV rated for RV use (like GasStop). GasStop is for use on 20lb and 30lb tanks as these tanks can generate the required flow rate to trigger it in the event of a sudden and catastrophic leak.

-

It is highly recommended that you do so. We view this as best practice when assessing the safety and integrity of your propane gas system. GasStop alone is not a guarantee of safety, it forms only one part of a total package of safety.

-

To ensure the fitting is gas tight, for most fittings hand tightening is not sufficient. Ensuring your gas appliances and gas system are tight and leak free is essential and recommended across the industry. Always read our instructions before use.

-

If installed correctly GasStop will shut-off if there is a sudden and catastrophic leak on your system (up to 19ft from the GasStop valve on 0.31″ hose/pipe diameter with an outlet pressure of 87 psig from your cylinder).

As a first step, make sure you have followed the installation instructions fully. Check that the GasStop gauge is facing the sky and has been pushed down at least 4-6 times.

If no sudden and catastrophic leak is present it may be that a high demand appliance or regulator is being used, drawing too much propane through the GasStop causing it to trigger. It may also be that you are operating your system in very low temperatures. If your GasStop is shutting-off unexpectedly and you need further assistance please contact us directly via the support tab on our website, our team will reply to you within 24 hours.

GasStop features and specs

-

GasStop will only shut-off in the event of a sudden and catastrophic propane leak. A leak that progresses over longer than 1 second, or a slow/minor leak will not trigger GasStop. GasStop is calibrated to offer sudden and catastrophic leak protection while allowing the operator to use their RV propane system as expected under normal working conditions. To achieve this balance between protection and operating convenience, a sudden and catastrophic leak is defined as a sudden and dramatic change in the gas flow rate equivalent to a flow rate of 78 standard cubic feet per hour (SCFH) or more. This excessive flow condition is why these types of valves are named ‘Excess Flow Valves’, EFVs for short. A real world example of a ‘sudden and dramatic change in the gas flow’ is the complete and immediate rupture of a propane hose. Furthermore, GasStop is calibrated to shut-off at ≥125% of the guaranteed flow rate, this is a UL requirement.

If GasStop were to be calibrated to shut-off for all types of leak (minor, slow, progressive), this would interfere with the ‘normal’ usage/consumption of your gas appliance(s), GasStop would shut-off every time you use your appliance(s). We have therefore calibrated the device to shut-off for sudden and catastrophic leaks only. With this in mind, we strongly advise that you use your GasStop to test for leaks, prior to using your propane system. Here’s a link on how to do so: https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1739_1

As a final point, GasStop offers up to 19 feet of protection against sudden and catastrophic leaks (0.31″ hose/pipe diameter) with an outlet pressure of 87 psig from your cylinder.

-

In the USA, all pigtail hoses (and some pressure regulators) have excess flow valves (EFV’s) built-in to them. It is important to note that on the rare occasion, faulty excess flow valves in pigtail hoses can stick in “bypass” mode. Bypass mode means that the flow of gas is mechanically limited through the hose. Hoses jammed and stuck in bypass mode will prevent normal pressure equalization of the system and will limit the flow of propane through the system. Normal pressure equalization and a guaranteed flow rate is a requirement for GasStop to function as advertised.

Note also, if the hose is stuck in bypass mode, your appliances will very likely not function as advertised either, as the propane flow will be severely restricted.

When installing and priming the GasStop, you should hear a clicking sound coming from the hose connector – this is the flow limiter deactivating, equalizing the pressure and allowing a full flow of propane. As soon as your system is fully equalised, GasStop will be protecting you from sudden and catastrophic leaks. If you are in doubt about anything please contact our team directly at info@gasstopglobal.com

-

No. GasStop will not shut-off in the event of a minor/slow/progressive leak. Refer to “How does GasStop define a sudden and catastrophic leak?” for a detailed breakdown of the limitations of the shut-off function here: https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1770_28

To achieve a balance between protection and operating convenience, GasStop cannot be calibrated to shut-off the propane system for all types of leaks. However, GasStop can be used to test for all types of leaks, here is how:

It is highly recommended that you always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to conveniently test your entire system from the propane cylinder locker. This test is known as a ‘visual lock-up pressure test’, also known as a pressure tightness test or a pressure decay test. We also encourage the use of soapy water to visually identify leaks by manually inspecting the lines and joints for bubbles (showing the escape of propane).

This test can only be carried out prior to normal gas usage.

To test your system for leaks:

- Set up your system (with your GasStop) as described in the user manual. Turn off the service valve on the gas cylinder. Now turn off all of your gas appliances. There should be no flow of propane in your system at this stage of test procedure.

- Now turn the propane cylinder back on at the service valve (make sure it is fully on). Keep all appliances off for the time being.

- Pump the pressure gauge on the GasStop up and down steadily and fully at least 4 to 6 times.

- The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder service valve is not open, GasStop has shut-off (or can’t pressurize), the propane has run out or you have not carried out sufficient pumping. Contact us directly to troubleshoot this step if necessary.

- Now turn off the service valve on the propane cylinder. Register the exact position of the needle on the gauge. Wait for 10 minutes.

- At this point, pressurised propane is now held between the GasStop and your appliances.

- If the needle has dropped from its initial registered position within 10 minutes there may be a leak (pressure decay). Do not use the gas system until the leak has been identified and/or repaired by an approved propane service technician and/or specialist.

- If, after pumping, the needle remains in the same position for at least 10 minutes, you can carefully start to use the system.

-

Yes, the two devices can be used together without interference. Unlike GasStop, an Over Pressure Shut-Off valve (OPSO) is not designed for sudden and catastrophic leak protection. For more information on GasStop vs OPSO valves, you can watch a useful explainer video here.

-

Yes. GasStop can be used with an automatic or manual changeover gas pressure regulator, regulated to a pressure of no higher than 20″ W.C with a capacity of no higher than 1.5 kg/h. A GasStop will need to be installed and pressurized/primed on each tank attached to the changeover device. It is very important that both installed GasStops are actively ‘reading” the pressure and flow in the total system.

-

It is important to note that using propane whilst driving is regulated by country and by state. Please consult with your RV manufacturer, a certified professional and the appropriate regulation before using gas while driving. GasStop can be used on your gas system while driving, but it is not recommended to use propane while driving. If installed correctly, a GasStop will offer protection against a sudden and catastrophic leak (for a detailed breakdown of the limitations of the shut-off function refer to: https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1770_28 )

Furthermore, GasStop can be installed alongside a crash sensor valve. A crash sensor valve may offer added protection in the event of a collision. GasStop is not a crash sensor valve. For limitations on a crash sensor valve please refer separately to the manufacturer/user manual of your specific device.

The two safety devices together fulfil separate yet important functions in the overall safety of your propane system.

-

Yes, GasStop can be used on regulators rated up to 20″ W.C.

-

Yes. GasStop can be used alongside a crash sensor valve, regulated to a pressure of no higher than 20″ W.C with a capacity of no higher than 1.5 kg/h.

-

GasStop is currently only for use on propane gas cylinders.

-

Yes. GasStop must be used with a propane pressure regulator to function correctly. GasStop is designed to be used with regulators rated up to 20″ W.C.

-

In the USA, propane cylinders have inbuilt OPD valves. An OPD valve is an overfill protection device, and as the names suggests will prevent the overfilling of a propane cylinder. GasStop is an Excess Flow Valve (EFV). It is designed to shut down 100% of the flow of propane in the event of a sudden and catastrophic leak. To protect against sudden and catastrophic leaks make sure you install a GasStop.

-

No, it reads the pressure of the propane under load/usage. Refer to: “Is the pressure gauge useful?” for a more detailed breakdown of what the gauge can be used for and what it can tell you.

-

No. Please refer to the information on our packaging or the retailer for case by case compatibility.

-

GasStop is made from high quality, surface treated brass and can withstand being left outdoors. Our gauge face is made from reinforced polycarbonate. As with any brass device, weathering will happen over the course of many years. To slow this process we highly recommend covering your GasStop when not in use. Every GasStop purchased in the US has a 5 year warranty with proof of purchase.

-

The propane pressure gauge is a very useful, multipurpose tool.

The propane pressure gauge is a very useful, multipurpose tool.- The gauge indicates when the propane cylinder is almost empty (a decline in the vapour pressure curve). The gauge does not indicate the exact amount of liquid propane left in the propane cylinder.

- A steady pressure reading (the needle is stable in the green or low part of the yellow zone) only indicates that there is propane in the cylinder.

- If the needle is pointing to:

– HIGH: Increased gas pressure.

– GAS: Normal gas pressure.

– LOW: Low gas pressure. Liquid propane may have been used up and your appliances are now drawing from the remaining propane gas vapour, represented by a pressure drop. We estimate that when the needle is in the red zone you have approximately 30 minutes left of propane use. - As GasStop is directly installed into the cylinder there are a few variables that can affect unregulated pressure, namely: temperature, amount of liquified gas vs rate of vaporization, gas type and gas purity. There may also be other irregularities which affect the pressure reading.

- As per the instructions, it is advised to run your propane for a small period of time to have a better indication of gas pressure. This allows the propane/pressure to reach something called “phase equilibrium”. Further to this point there is a “vapour pressure curve”, this is why it is recommended to run the bottle for a short while to allow for this process.

NB the gauge is also useful to represent the following:

- Visual evidence of pressure decay (a leak) in a lock-up pressure test scenario.

- Visual evidence of high pressure

- Visual evidence of a shut-off

- Visual evidence of an activated and stable system

- Visual evidence of variable/unstable pressure

-

Flow limiters built-in to common US propane connectors may not shut the propane off completely in the event of a sudden and catastrophic leak, they often just limit the flow. GasStop completely shuts off the 100% of the supply of propane in the event of a sudden and catastrophic leak. GasStop will give the operator a visual representation of the status of the propane flow and pressure.

-

First, check that you have installed your GasStop correctly and pushed down on the gauge at least 4 to 6 times. If this does not work, check your system for leaks, it may be that GasStop cannot pressurize due to a loose line or connector. If these steps do not work, please contact us directly.

-

Leaks downstream should be taken seriously. The pressure differential created in a sudden and catastrophic leak (downstream) will be ample to empty a full propane cylinder very quickly. 11” W.C is ample pressure to supply enough propane to power furnaces, stoves etc, it is therefore enough to pose major safety risks if left unchecked.

-

In humid, cool or changeable weather conditions, condensation may appear on the inside surface of the transparent gauge face. This happens as the air trapped inside the gauge condenses, forming small surface water droplets on the plastic casing. Although this is not common, it will not affect the operation of the GasStop. To rectify the problem, remove your GasStop from the gas system and leave the product in a warm and dry location. After a while the condensed water will evaporate and the visual appearance of the gauge will return to normal.

-

GasStop is a type of Excess Flow Valve (EFV) that will completely (100%) and automatically shut-off the supply of gas in the event of a sudden and catastrophic leak (for a detailed breakdown of the limitations of the shut-off function please refer to:https://gasstopusa.com/about-the-gasstop/frequently-asked-questions/#q_1770_28 ). GasStop must be reset manually, giving the user complete control.

A self-equalizing EFV (Excess Flow Valve) manages the reset function automatically. To do so, it often cannot completely shut-off 100% of the flow of propane, in order to be able to ‘see’ the pressure equalization downstream from its position. These types of EFVs are often found in pigtail hoses and are often described as flow limiters rather than total shut-off devices.

-

GasStop propane devices are rated to operate between -4 °F and 131 °F. However, at low temperatures, GasStop may shut-off more readily when used with higher demand appliances and/or on longer length pipework. See ‘Will GasStop operate normally at low temperatures?’ for more information.

-

You may notice that in colder temperatures (approaching 0°C/32°F), an EFV (GasStop) may shut-off more readily when used with higher demand appliances and/or on longer length pipework. For optimum performance during colder temperatures orientate your GasStop so that the gauge is facing the sky and make sure you push down on the gauge fully at least 5-6 times. .

-

No. GasStop has a maximum range of protection. GasStop provides protection for up to 19 ft of 5/16″ (8 mm) ID propane line at 11″ W.C. and approximately 16 °C, under light appliance use such as a refrigerator.

On systems with a ½″ trunk line, the same EFV typically provides protection for up to ~21 ft under equivalent conditions.

Actual protection distance may be reduced by regulator pressure droop, additional fittings, or higher simultaneous gas demand

-

No. Many propane fuelled generators and/or welding machines consume a large volume of propane, meaning they draw a high rate of flow, especially at start-up. GasStop is designed to shut-off when that rate of flow suddenly exceeds 78 SCFH (this is what happens during a sudden and catastrophic leak). Generators (even smaller models) and welding machines may ‘mimic’ this high flow rate scenario, thus effectively tripping GasStop into ‘catastrophic leak mode’.

Quality and compliance

-

GasStop cannot be CE marked because it does not fall within the scope of CE marking. This does not mean the GasStop doesn’t meet the quality demands of CE, what it means is simply the standardised legislation/directive does not cover GasStop at present.

The Pressure Equipment Directive (PED) is the nearest applicable directive and GasStop meets “Sound Engineering Practice” (voluntarily) under this directive. In other words, GasStop meets the maximum requirements (permitted under the directive) required by the PED.

-

Yes, GasStop is UL listed. Furthermore each and every GasStop is rigorously tested. All of our testing is evidenced via a global third-party test auditor.

-

All GasStops sold in the USA are tested to UL 119 and UL 2061 standards. As all US models of GasStop are tested to both standards GasStop is suitable for use on both fixed and portable cylinders. Both UL 119 and 2061 clearly reference NFPA 1192, see chapter 5 covering fuel systems and equipment.

-

We hope this will change in time, but for now GasStop is available to purchase and install as an aftermarket option.

More information

-

How to use

Learn how to use the GasStop in a few simple steps - or watch our explainer video.

-

Quality assured

The GasStop adheres to all revelant standards and has undergone a thorough testing process.

-

Frequently asked questions

Got questions? Find the answers in our FAQ.

-

5 year warranty

Find out more about our 5 year warranty here.

Get your GasStop today

GasStop is available to buy at the online and physical stores shown below.

Get the correct type: POL for motorhomes — ACME for 5th wheels and trailers.